Einleitung

This guide shows how to remove and replace the entire pump assembly as a whole unit for the Mi-T-M gas pressure washer.

You have to remove the output assembly from the pump in order to replace the pump assembly. This requires removing many tight pipe fittings.

You will need something that is 3” tall to place underneath the pump assembly. This can be a wooden block, brick, etc. This will help brace the pump while you work on removing the fittings.

The following tools are optional, but can help with disassembly:

- 1/4” socket

- 11/16” wrench

- 3/4” wrench

- 15/16” wrench

- 1” wrench

Was du brauchst

-

-

There are two versions of the unloader assembly:

-

First image—earlier pressure washers feature an all-in-one assembly (part 8-0631) that’s easy to replace, but gave users the ability to break the pump.

-

Second image—later models use a tamper-proof, harder to remove unloader (part 8-0656), connected by a series of pipe fittings.

-

If you need to remove an all-in-one style unloader, use a large adjustable wrench to unscrew the two large Banjo bolts. This will disconnect the unloader from the pump assembly.

-

-

-

Grab the plastic housing at the end of the spark plug wire.

-

Pull firmly to disconnect the wire from the spark plug.

-

-

-

Use a 1/4" socket or a large flathead screwdriver to loosen the hose clamp near the inlet filter.

-

Slide the hose clamp away from the end of the hose.

-

-

-

Wiggle the hose and pull it off of the brass nipple.

-

-

-

Slide a 3" tall block underneath the pump assembly to help support the pump.

-

-

-

Use a 1/2" or adjustable wrench to loosen and twist the return elbow half a turn, so that it faces the opposite direction.

-

-

-

-

Use a large adjustable wrench to loosen and unscrew the filter.

-

-

-

Use a 1" or large adjustable wrench to loosen and unscrew the pump input elbow.

-

-

-

Use a 3/4" or adjustable wrench to loosen and disconnect the coupling from the pump assembly.

-

-

-

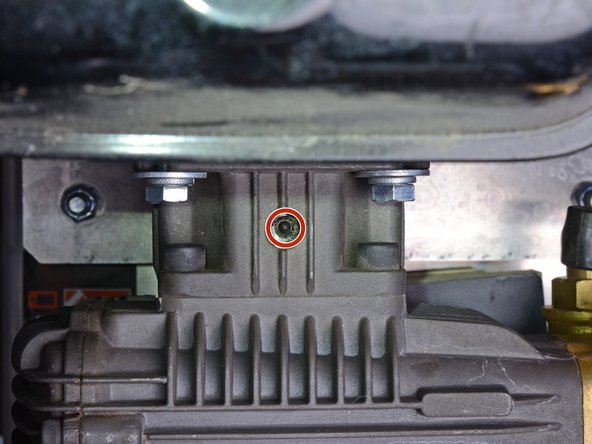

Look through the top access hole on the pump, near the engine coupling. You should be able to see the pump shaft through the hole.

-

Slowly pull the starter cable. This will slowly turn the engine's axle.

-

Keep rotating the axle until you can see the set screw through the access hole.

-

-

-

Insert a 2.5 mm hex key into the set screw and loosen it counter-clockwise by two full turns.

-

-

-

Use a 1/2" wrench to remove the four 30 mm long bolts which mount the pump to the engine.

-

-

-

Carefully pull the pump assembly away from the engine until it de-couples from the engine axle.

-

-

-

Remove the axle key from either the engine axle, or the pump shaft.

-

-

-

Press the axle key into the notch on the engine axle.

-

Align the pump shaft with the keyed axle. You may have to rotate the pump to do so.

-

Slide the pump onto the axle until the coupling surfaces touch.

-

To reassemble your device, follow these instructions in reverse order.

When you re-connect the fittings, clean off the old thread sealant and apply new thread sealant (tape or pipe dope).

To reassemble your device, follow these instructions in reverse order.

When you re-connect the fittings, clean off the old thread sealant and apply new thread sealant (tape or pipe dope).